YOUR PART. LOCALLY MADE.

*Deutsche Version s.u.*

Innovative plastic solutions – fast, precise, and sustainable.

SK Industriemodell GmbH, based in Übach-Palenberg, is a pioneer in advanced plastic processing. As a specialist in injection-molded prototypes and small series production, we offer a fully integrated in-house manufacturing process – from the initial idea to the finished component. Our customers benefit from maximum flexibility, short development cycles, and top-tier quality.

Our Core Competencies:

Development & Design: We support projects from concept to production readiness – with technical expertise and creative solutions.

Toolmaking: Our in-house tool shop produces precise aluminum and steel molds tailored to specific customer requirements.

Additive Manufacturing: By using 3D-printed injection inserts, we shorten development times and enable rapid iterations.

Injection Molding: Whether prototype or small batch – our production is optimized for precision and efficiency.

Technology Partnerships: In close collaboration with leading research institutions, we continuously develop new processes and materials for plastic manufacturing.

Sustainability: Regional production, resource-efficient processes, and durable products are part of our DNA.

Project Highlight: The “Strawberry Wall”

For the “Strawberry Wall” project, we combined speed, material expertise, and manufacturing excellence:

Material Selection: We sourced a plastic material with food-contact approval and high mechanical stability – ideal for use in food-related environments.

Tooling & Components: Within just 14 days, we designed and manufactured the injection molds and produced the first components – a showcase of our agile approach.

Production: The components were manufactured on a Tederic injection molding machine, ensuring high precision and process reliability.

This project demonstrates how technical precision, collaborative partnerships, and rapid execution come together at SK Industriemodell – delivering solutions that inspire.

For more information on SK Industriemodell visit our Website and check out our LinkedIn.

_________________________

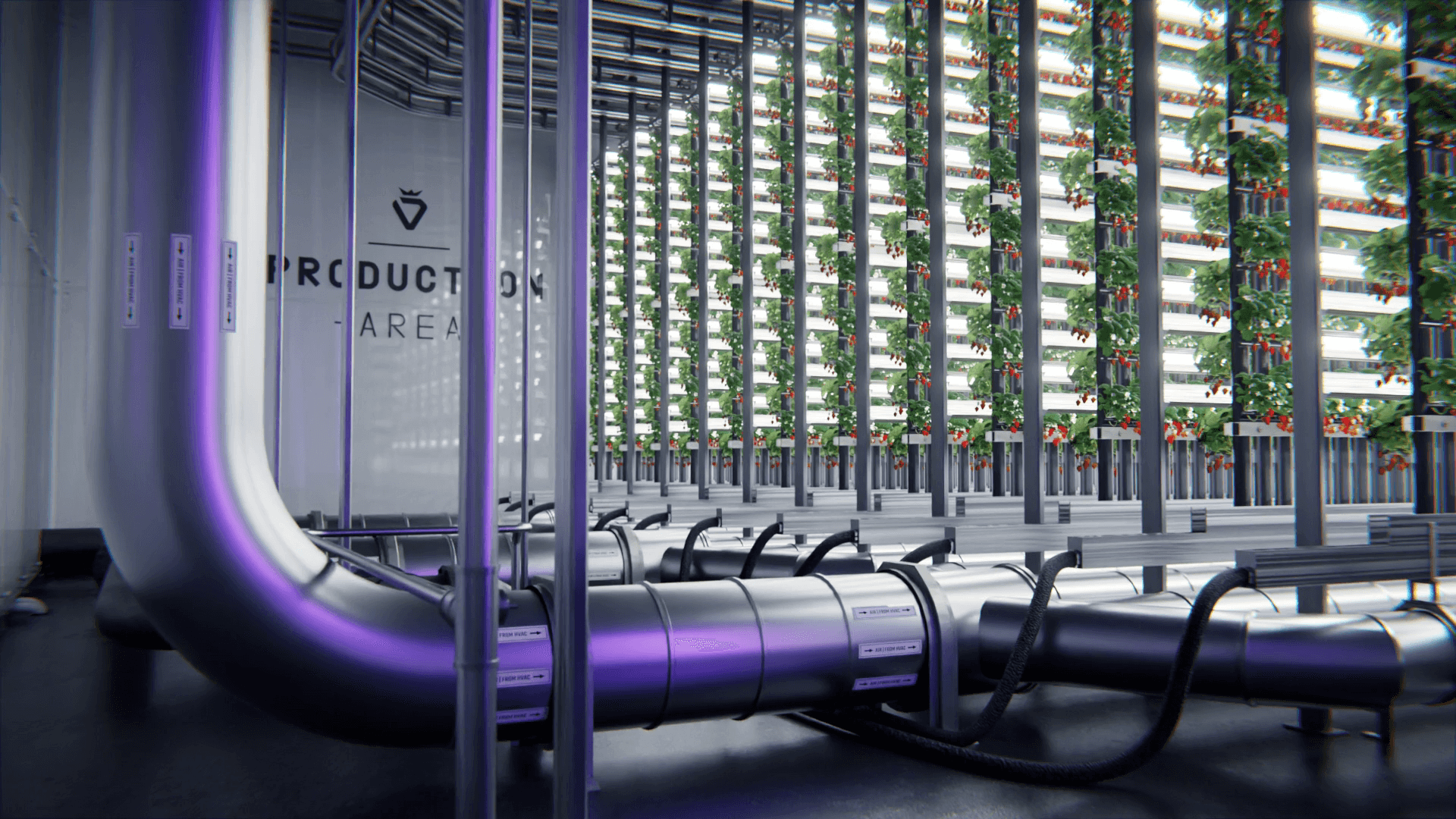

vGreens – Intelligent Systems for Controlled Food Production

Maximum Yield. Predictable Quality. Future-Proof Farming on Minimal Space.

vGreens develops modular production systems that enable growers to cultivate food more efficiently, sustainably, and precisely—independent of location or conditions. By combining tailor-made hardware with our vGreensLab software platform, the system transforms sensor data and biological signals into precise, AI-driven decisions in real time.

The result: higher utilization, consistent quality, and optimized operating costs in every harvest cycle.

The vGreens Advantage

Effective Space Utilization: 100% higher plant density per m³ translating to higher yield.

Lower Resource Use: Optimized efficiency in water, energy, and CO₂ consumption.

Faster Payback: Scalable systems that minimize investment risk.

Predictable Quality: Consistent standards and data-driven control ensure stable prices and reliable supply.

System Design for Profitable Production

Flexible scalability: from compact urban sites to large-scale facilities.

CapEx-light options reduce entry costs.

Adaptable to your business goals: from yield maximization to premium quality production.

Technology That Creates Lasting Value

Real-Time Sensor Data detects exactly what the plant needs—moment by moment.

AI-Controlled Automation reduces manual intervention and labor costs.

Continuous Feedback Loop: Each harvest improves the next, driving efficiency and predictability over time.

The vGreens system is built for food producers, integrators, and distributors. A fully operational industrial-scale module can be visited at our site in Essen, Germany.

For more information visit our Website and check out our LinkedIn.

Gallery

DE

DEIN TEIL. LOKAL GEFERTIGT.

Innovative Kunststofflösungen – schnell, präzise und nachhaltig.

Die SK Industriemodell GmbH aus Übach-Palenberg steht für zukunftsweisende Kunststoffverarbeitung „Made in Germany“. Als Spezialist für Spritzguss-Prototypen und Kleinserien bieten wir eine vollständig integrierte Inhouse-Fertigung – von der ersten Idee bis zum veredelten Bauteil. Unsere Kunden profitieren von maximaler Flexibilität, kurzen Entwicklungszyklen und höchster Qualität.

Unsere Kernkompetenzen:

Entwicklung & Konstruktion: Wir begleiten Projekte von der Konzeptphase bis zur Serienreife – mit technischer Expertise und kreativen Lösungen.

Werkzeugbau: Im eigenen Werkzeugbau entstehen passgenaue Aluminium- und Stahlformen, die individuell auf Kundenanforderungen abgestimmt sind.

Additive Fertigung: Durch den Einsatz 3D-gedruckter Spritzgusseinsätze verkürzen wir Entwicklungszeiten und ermöglichen schnelle Iterationen.

Spritzgussfertigung: Ob Prototyp oder Kleinserie – unsere Fertigung ist auf Präzision und Effizienz ausgelegt.

Technologiepartnerschaft: In enger Zusammenarbeit mit Forschungseinrichtungen entwickeln wir neue Verfahren und Materialien für die Kunststoffverarbeitung.

Nachhaltigkeit: Regionale Fertigung, ressourcenschonende Prozesse und langlebige Produkte sind Teil unserer DNA.

Projektbeispiel: Die Erdbeerwand

Für das Projekt „Erdbeerwand“ haben wir unsere Stärken in Geschwindigkeit, Materialkompetenz und Fertigung vereint:

Materialauswahl: Wir haben ein Kunststoffmaterial mit Food-Contact-Zulassung und hoher mechanischer Stabilität beschafft – ideal für den Einsatz im Lebensmittelumfeld.

Werkzeugbau & Bauteile: Innerhalb von nur 14 Tagen wurden die Spritzgusswerkzeuge konstruiert, gefertigt und die ersten Bauteile produziert – ein Paradebeispiel für unsere agile Arbeitsweise.

Produktion: Die Komponenten wurden auf einer Tederic-Spritzgießmaschine gefertigt – für höchste Präzision und prozesssichere Herstellung.

Dieses Projekt zeigt, wie technische Präzision, partnerschaftliche Zusammenarbeit und schnelle Umsetzung bei SK Industriemodell zusammenkommen – für Lösungen, die begeistern.

Für mehr Informationen über SK Industriemodell besuchen Sie unsere Website und unser Profil auf LinkedIn.

_________________________

vGreens – Intelligente Systeme für die Lebensmittelproduktion von morgen

Maximale Erträge. Planbare Qualität. Zukunftssichere Landwirtschaft auf kleinster Fläche.

vGreens entwickelt modulare Produktionssysteme, die Erzeugern ermöglichen, Lebensmittel effizienter, nachhaltiger und kontrollierter anzubauen – unabhängig von Standort und Rahmenbedingungen.

Die Kombination aus maßgeschneiderter Hardware und der Softwareplattform vGreensLab verwandelt Sensordaten und biologische Signale mithilfe von KI in präzise, automatisierte Entscheidungen in Echtzeit.

Das Ergebnis: höhere Auslastung, kalkulierbare Qualität und optimierte Betriebskosten – in jedem Erntezyklus.

Die Vorteile mit vGreens

Effiziente Flächennutzung – 100 % höhere Pflanzendichte pro m³, was zu einem höheren Ertrag führt.

Weniger Ressourceneinsatz – optimierte Nutzung von Wasser, Energie und CO₂

Schnellere Amortisation – skalierbare Systeme, die Investitionsrisiken minimieren

Planbare Qualität – gleichbleibende Standards sichern bessere Marktpreise

Systemdesign für profitable Produktion

Flexibel skalierbar: von urbanen Flächen bis zu Großanlagen

CapEx-light-Optionen reduzieren Einstiegskosten

Anpassbar an Ihre Geschäftsziele – Ertragsmaximierung oder Premiumqualität

Technologie, die nachhaltig Wert schafft

Sensordaten in Echtzeit – erkennen, was die Pflanze braucht

KI-gesteuerte Automatisierung – reduziert manuelle Eingriffe und Personalkosten

Kontinuierlicher Feedback-Loop – jede Ernte steigert Effizienz und Planbarkeit

vGreens richtet sich an Lebensmittelproduzenten, Integratoren und Distributoren. Ein vollständig funktionsfähiges Industriemodul kann an unserem Standort in Essen besichtigt werden.

Weitere Informationen finden Sie auf unserer Website und LinkedIn.

Contact SK Industriemodell GmbH

Sebastian Krell, CEO

sebastian.krell@sk-industriemodell.de

Contact vGreens Holding GmbH via contact form below.